Reference 46 Marupes

AIR SOLUTIONS TO GET A HOMOGENOUS MICRO CLIMATE

1. Flexible and customised solutions

Solutions specifically customised to your project and designed to ensure homogenous air distribution and optimal micro climate.

2. Efficient air distribution

The system has a high inductive outlet pattern that provides a good mixture of the injected air with the air that is already in the growing area.

Due to the position and our hole pattern, you obtain a lower temperature in the crop of the plant.

3. Unique design

With this specifically developed duct for greenhouses we have found the right balance between the dynamic and static pressure.

This is why the air flow at the beginning and at the end of the duct is more uniform than in any other system.

4. Patent

The duct system has a uniquely designed, patented and highly inductive outlet pattern. This unique outlet pattern ensures a very good mixture of the injected air with the air that is already between the leaves and in the growing area.

5. Entrainment

Entrainment is an undesired parallel airflow along the air distribution duct in the direction of the airflow, which is usually created in air distribution ducts with only a normal hole pattern. Entrainment is a major cause of poor air distribution in greenhouses. Due to the slanted outlet, there are high air speeds and a shortage of air at the beginning of the air distribution duct and an excess of air at the end.

6. Less energy consumption

Due to the single duct concept and a balanced ratio between the selected ventilator and the air distribution duct, the power consumption of the ventilator is considerably less, resulting in lower energy consumption or a larger quantity of air supply.

7. UV-stabilised

The material is transparent or white polyethylene (PE) and is UV-stabilised [320 Kilo Langley per Year (KLY); 80 KLY is one year of UV in the Netherlands].

The thickness of the material is 150 or 180 micron. It is produced in three layers, resulting in a material that can optimally withstand cracking (breaking by continuous movements).

8. Easy to mount

An additional advantage of a single hose is the easy mounting: you have to mount only a single duct and that will save you time. You don’t have to consider the second duct which will be inside the outer duct that can move with the installation. The weight is many times lower so that you can install a lighter suspension construction. When replacing the ducts, you have to pay only half the amount of environmental tax for transporting the discarded plastic

THE GROWAIR® SOLUTION IS BASED ON A PATENTED SYSTEM DESIGNED WITH HOLES IN COMBINATION WITH FLOW CONTROLLING DIRECTION BAFFLES.

THIS WILL REDUCE THE AIR FLOWING ALONG THE DUCT AND ENSURE A UNIFORM AIR DISTRIBUTION AND OPTIMAL MICRO CLIMATE.

More even air distribution in the length and height of the duct

Lower overall pressure loss

Takes less time to install due to the GrowAir® duct patented pattern system, only requires one duct

The patented pattern in the GrowAir® system will be made in such a way that the entrainment problem seen on the Double Duct system will be balanced more out

More uneven air distribution in the length and height of the duct

Higher overall pressure loss due to the Double Duct system

Takes longer time to install due to the Double Duct system

Entrainment may occur in the first part of the system, leading to less air in the area where the ducts are connected to the fan

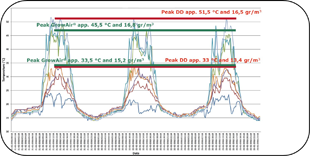

In the shown pilot there is a temperature and absolute humidity difference during the day. We have measured a difference of 6°C near the top of the plant between the Double Duct and the GrowAir® duct. At night the temperature and humidity is more uniform (1°C). Looking at the absolute humidity the GrowAir® duct creates a more homogenous distribution. Please note that in this pilot we have not changed the inlet conditions of the acclimatized air, so it is the same for the Double Duct and the GrowAir® duct.

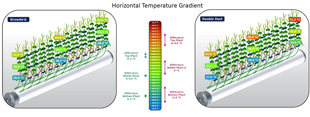

The GrowAir® duct has over 120 meters a horizontal temperature difference of 1°C at the bottom and 2°C at the top of the plants The Double Duct has a horizontal temperature difference of 6°C at the bottom and 4.5°C at the top of the plants over 120 meters.

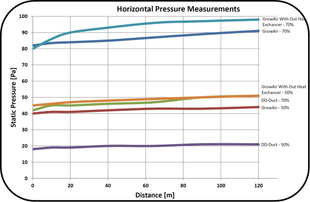

Due to the construction method of the GrowAir® duct system there is a higher static pressure available to force the air out of the holes. This has a significant influence on the air velocity and the potential possible reachable height for the air leaving the ducts

In this project the static pressure in the Double Duct after 65 m is 47 Pa at 70% Fan Speed, which is much lower than the GrowAir® system that has a static pressure left of 85 Pa at 65 metres at 70%

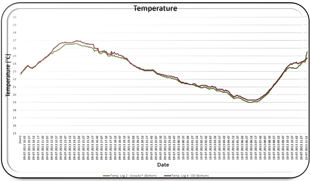

The temperature in the duct is equal for GrowAir® and Double Ducts, there is absolutely no isolation activity from the two polyethylene ducts that makes a double duct

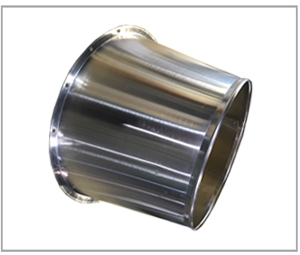

The plenum connects the fan or air handling unit with the GrowAir duct.

The plenum connects the fan or air handling unit with the GrowAir duct and because of the air guidance blades you will have even less turbulence in the first meters of your duct.

This end cap need to be installed at the end of your duct. The holes will supply some air in the middle pad and haze a fixing point to adjust the duct to the gutter on the end.

This end cap need to be installed at the end of your duct. The adjustable holes will supply some air in the middle pad and haze a fixing point to adjust the duct to the gutter on the end.

To hang the duct under the total gutter we supply you a special suspension kit with syntactic hooks.

To connect the duct to the plenum and air handling unit/ventilator and end-cap you need these specific clamps.

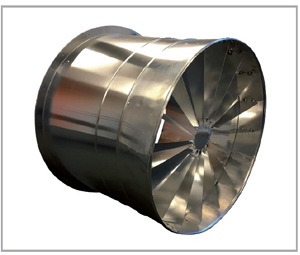

In semi closed greenhouses it is common to use a corridor to mix the air to create optimal conditions. The air will be transported out of the corridor by a fan into a plenum and air distribution ducts. The fan and the air distribution system have to be in balance with each other to get an optimal working system for gaining optimal conditions to grow in. We can advise, select and supply you with a specially selected fan to reassure you a well-balanced system for an optimal homogenous air distribution in your (clients) greenhouse.

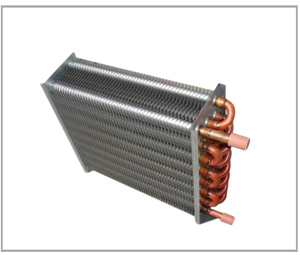

In semi closed greenhouses it is common to use a corridor to mix the air to create optimal air conditions. In some conditions it is advisable to extent your air distribution system and fan with a heat exchanger. We can advise, select and supply you with a specially selected heat exchanger to reassure you a well-balanced system for an optimal homogenous air distribution in your (clients) greenhouse.

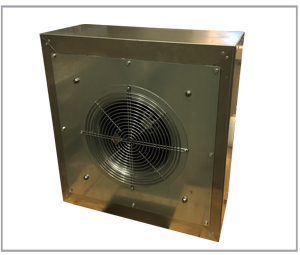

In some situations creating a corridor is not possible or unwanted. For this situations the best air conditions will be created in an air handling unit/dehumidifier. Depending on the situation this unit is placed outside the greenhouse or inside it (and has a connection with the outside to get fresh air. We can advise, select and supply you with a specially selected air handling unit/dehumidifier to reassure you a well-balanced system for an optimal homogenous air distribution in your (clients) greenhouse.

If air need to be mixed in your greenhouses to create optimal conditions, we can provide you with this Ventilatorbox including a plenum and air distribution ducts. The fan and the air distribution system have to be in balance with each other to get an optimal working system for gaining optimal conditions to grow in. We can advise, select and supply you with a specially selected fan to reassure you a well-balanced system for an optimal homogenous air distribution in your (clients) greenhouse.

Reference 46 Marupes

Reference 45

Reference 44Active recirculation ventilation

Reference 43Active recirculation ventilation

Reference 42Active recirculation ventilation

Reference 41Active recirculation ventilation

Reference 40ADB

Reference 39Solace

Reference 38Zea Mais research

Reference 37Den Magiske Fabrikken

Reference 36Vertical Farm 1

Reference 35Container climate conditioning

Reference 34Shelf climate conditioning

Reference 33Energy to Save Anthuriums

Reference 32Homogenous Climate

Reference 31Tom d’Aqui pilot

Reference 30Cooling Wasabi

Reference 29Les Jardins du Reunis

Reference 28FMO

Reference 27Eletsk part 1

Reference 26Feduline

Reference 25Pomes

Reference 24Indoor Cultivation on the Highest Standards

Reference 23GROWx Vertical Farm

Reference 22Magnin 2

Reference 21Pozzobon

Reference 20Earl Du Chateau

Reference 19Enza Zaden

Reference 18Greenhouse nr 1.

Reference 17AgroKultura

Reference 16Incotec research & development

Reference 15Biobest Biological Systems

Reference 14Magnin

Reference 13Clement

Reference 12Wageningen University & Research

Reference 11 Stolze Installatietechniek B.V.

Reference 10Windset Farms

Reference 9Earl Perez & Fils

Reference 8JMP Flowers

Reference 7Fayard

Reference 6Ter Laak

Reference 5 Tomunion

Reference 4Limagrain

Reference 3Koppert Biological Systems

Reference 2JPL Provence

Reference 1Le Jardin de Rabelais